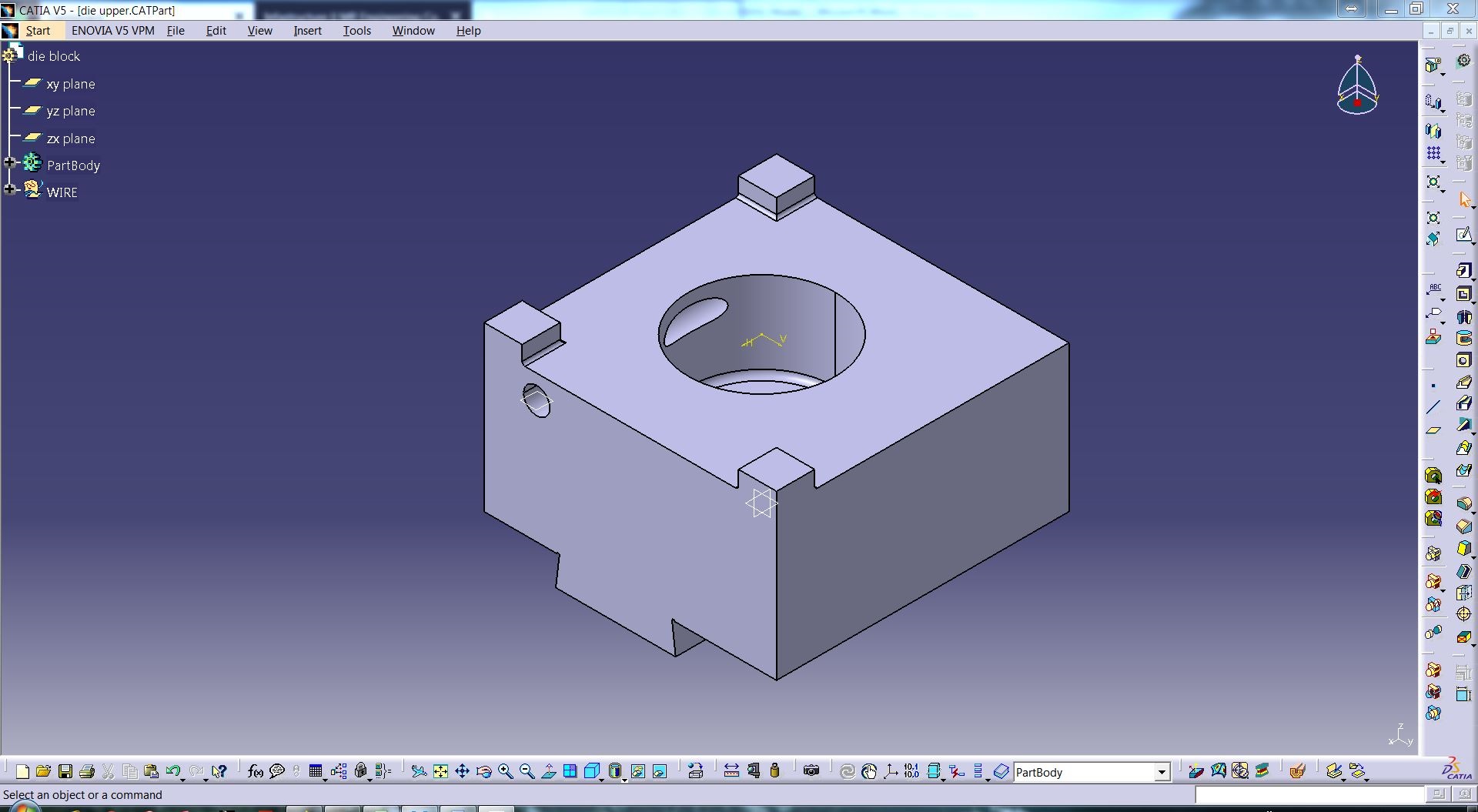

Die Designing

Latest technology clubbed with the vast knowledge of experience & well trained personnel assist us to get the results efficiently. With the help of technical tools & methods like 3D Modelling & Simulation we can comprehend the relevant forging process requirements.

M.R uses the best material flow simulation software known as DEFORM to analyses and predict the accurate grain structure formations The DEFORM® system is an engineering software that enables designers to analyses metal forming, heat treatment, machining and mechanical joining processes on the computer rather than the shop floor using trial and error. Process simulation using DEFORM has been instrumental in cost, quality and delivery improvements.

M.R uses the best material flow simulation software known as DEFORM to analyses and predict the accurate grain structure formations The DEFORM® system is an engineering software that enables designers to analyses metal forming, heat treatment, machining and mechanical joining processes on the computer rather than the shop floor using trial and error. Process simulation using DEFORM has been instrumental in cost, quality and delivery improvements.

CUTTING, A KEY STRENGTH TO PRODUCTION

To Be Competitive In The Market You Have To Strengthen The Basic To Your Work.

Cutting Is One Of The Most Important Infrastructure To Meet Your Customer Demands.

To Fulfill, We Have 3nos Of Automatic Bandsaw & 5Nos Manual Operated

Which Are Well Maintained And Regularly Service To Ensure Availability And Performance.

FORGING, A STEP TO LEAD

M.R. Initially Started A Forging Unit With More Than 25 Years Of Forging Experience. We Deeply Understand The Material Flow, Forging Techniques, Die Designing & Tooling.

M.R. Uses Infra Red Pyrometer For Accurately Monitoring Forging Temperature To Deliver Quality Products

To Meet The Demands

We Have 3 Closed Die Hammers, 1Tons, 2tons & 3tons

2 Trimming Presses 200tons & 100Tons

And 1 Pneumatic Hammers 1tons

Testing Facility

At M.R, we implement stringent Product testing & Inspection to ensure our products meet the customer requirements. Our inspection & testing capabilities includes:

●Chemical composition testing from NABL (National Accreditation for Testing & Calibration) approved lab.

●Mechanical Properties Testing.

●Ultra sonic Testing for detecting Internal defects like cracks, fold, etc.

●Hardness Testing

●Chemical composition testing from NABL (National Accreditation for Testing & Calibration) approved lab.

●Mechanical Properties Testing.

●Ultra sonic Testing for detecting Internal defects like cracks, fold, etc.

●Hardness Testing

Heat Treatments

We have our in house facility for Heat Treatment such as Normalizing, Flame Hardening, Sand Bath quenching, case hardening & Induction Hardening. All these in-house facility help us to provide our customer with a product which is free from residual stress with easy to machine able hardness, even formation of grain structure through the material & with dimensional stability.

M.R. also provides its customer with Annealed products. This Process are carried out by our high quality sources within controlled environment .

M.R. also provides its customer with Annealed products. This Process are carried out by our high quality sources within controlled environment .

Machinig

At M.R. we are focused to provide optimum satisfaction to our customer. This is done by offering a productive & qualitative Machining by well Maintained Lathe Machine & CNC Lathe Machine. These Service are highly appreciated for meeting the customer requirement with cost effectiveness.